Emissions reduction through optimised lube oil consumption

The global drive for a CO2 neutral means of transportation has pushed ICE modes of transportation to a new level of efficiency. As a contributor to CO2, lube oil consumption must be managed and reduced to a minimum level of lubrication for the components to survive the duration of the engine life. As we look to alternative energy within the ICE market, hydrogen becomes a potential natural fit with a net zero CO2 output at the tailpipe. However, lube oil consumption now sees an increased role as there is no lubricity within the fuel and being the only source of CO2 tailpipe emissions.

Our Value Add

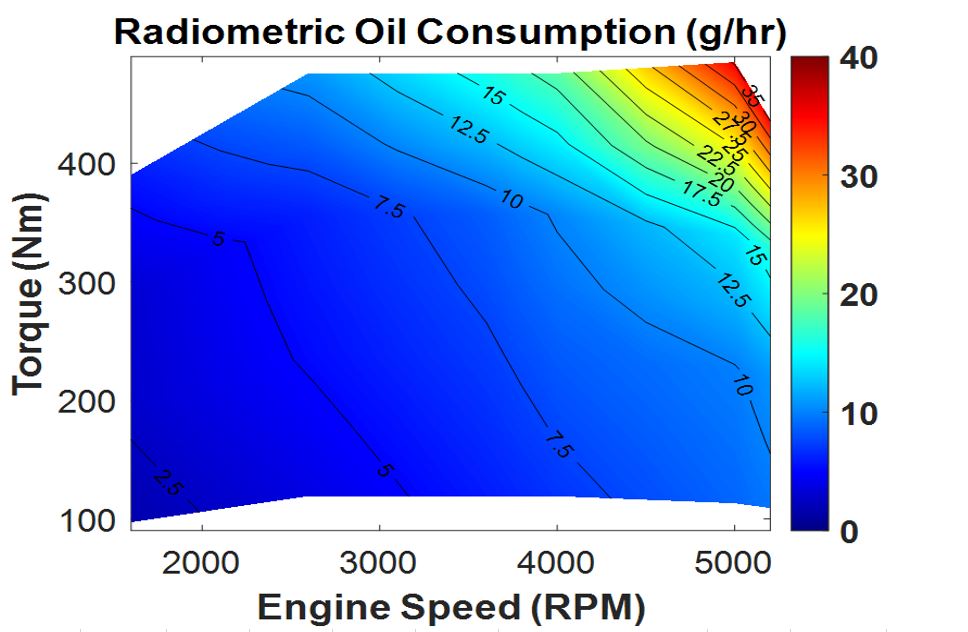

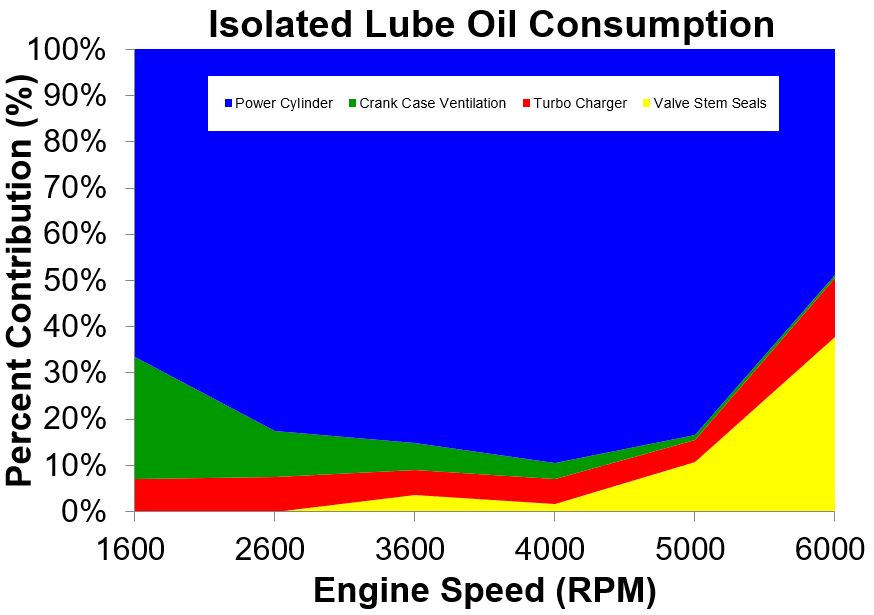

Over the past 40+ years, MAHLE has developed and implemented a state-of-the-art technology for measuring lube oil consumption, both burned and unburned, as a holistic measurement technique. The Tritium Tracer technology allows for the direct measurement of lube oil consumption of the entire engine while utilizing the OEM specified fuels and lubricants. Both steady state mapping (as shown in Figure 1) and transient cycle capturing are standard processes performed daily. Furthermore, the method allows for a direct measurement of the crank case ventilation system, as well as turbo charger lube oil consumption. Indirectly, the power cylinder assembly and the valve stem seal lube oil consumption can also be measured, as shown in Figure 2 (ASME ICEF2014-5404).

Our Tools, Facilities and Services

- Detection Limit: < 0.1 grams / hour

- Repeatability & Reproducibility (R&R) near 5%

- Proven excellent field correlation with multiple OEMs

- System analysis of overall engine, breather, valve stem seal, turbocharger and power cylinder; reference ASME technical paper ICEF2014-5404

- Steady state, transient and green engine break-in operation measurements

- Customer specified components, fuels and oils with a wide array of fuels on-site (mainstream and alternative)

- State of the art dynamometer test stands with diverse testing, control, acquisition and automation capacities

Customer Benefits

- Highest level of data quality available for lube oil consumption

- Fast mapping drastically reduces development time compared to other methods

- High flexibility and capability to run a wide range of fuels

- Cost effective as compared to alternative methods for measuring lube oil consumption

- Highest level of understanding the mechanisms and solutions to resolve lube oil consumption issues in-house