Build Services

Highly experienced technicians building top quality prototypes in a specifically tailored environment.

Vehicle Engineering Centre

Our Value Add

- Vehicle Engineering Centre (VEC)

- Fully equipped vehicle workshop with six vehicle build stations catering for engine and drivetrain installations, demonstrator vehicle builds and comprehensive instrumentation requirements

- Dedicated client bay with privacy curtains and separate access

- Skilled workshop technicians experienced in a wide variety of vehicle tasks

Our Tools, Facilities and Services

- Prototype vehicle development and vehicle integration [PDF; 2946 KB]

- Demonstrator, mule and small series vehicle builds

- Conversion or upgrade of donor vehicles into fully-functional demonstrators

- Hybrid powertrain installations

- From alternative engine installations to full REEV conversions

- Vehicle preparation for RDE testing with PEMS (VCA approved)

- Extensive modifications to induction, exhaust, cooling and fuel systems

- Fitting of test instrumentation and data logging test equipment

- Design and installation of prototype electronics

- Installation of EV battery, inverters, controllers and e-motors (wheel or chassis mounted)

- Wiring harness design, manufacture and installation

- In-house machining and fabrication support

- Secure, enclosed vehicle storage compound for up to 20 vehicles

- 2.5t vehicle transporter with fully enclosed body

MAHLE Powertrain’s highly skilled team are experienced in building prototype assemblies from V12 engines. The engine build facility is equipped with:

- 18 x engine build bays with computerised documentation / build records

- Ability to screen off build bays to provide confidential build areas

- Machining and fabrication support

- Instrumentation fitting for temperature, pressure, vibration and strain

- Hot test stands for integrity checking

- 3 stage component wash

Our Tools, Facilities and Services

- Well-equipped, in-house engine build shop

- Highly experienced engine build technicians

- Build of high performance engines for race applications

- Assembly of prototype and pre-production engines

- Secure room for engine strip and layout

- In-house machining and fabrication support

- In-house wash and metrology facilities

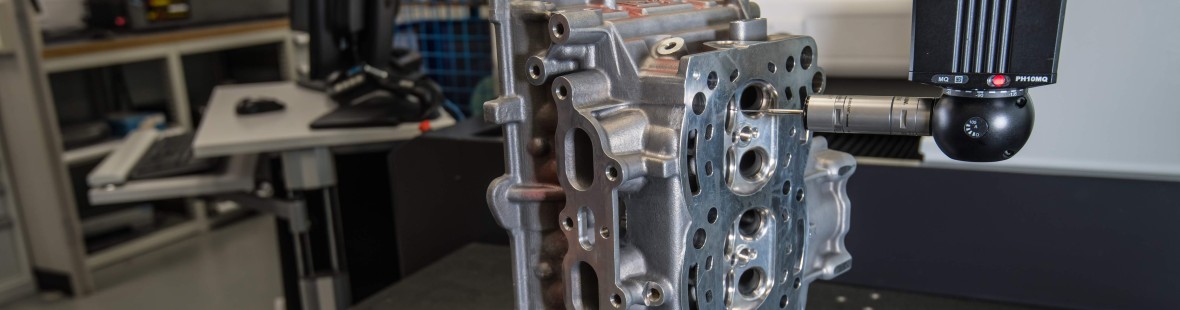

MAHLE Powertrain have developed a Supplier Quality Assurance, Logistics and Metrology service that offers:

- SQA engineer support for supplier and deviation management

- Inward logistics for components using SAP

- Temperature controlled metrology area, traceable to UKAS standards

- 3D Laser scanning FARO arm

- Mitutoyo Scanning CMM

- Valvetrain component measurement spring rates, camshaft profile etc