MAHLE Powertrain – Vehicle Development Centre

Our new Vehicle Development Centre (VDC), previously known as the RDE Centre, sits at the heart of our comprehensive RDE development process which also involves early stage emissions simulation, steady-state and transient powertrain testing and on-road PEMS / RDE testing during real-world driving scenarios.

Powertrain Test Facility of the Year

Our new Vehicle Development Centre was recently awarded Powertrain Test Facility of the Year 2022 (in conjunction with our new Battery Development Centre) by Automotive Testing Technology International magazine. Click here for more details.

RDE development process (video)

A state of the art vehicle emissions testing facility with transient altitude and climatic capability. Vehicles can be tested on the 4WD chassis dynos under widely variable altitude, temperature and humidity conditions. Both chambers are fitted with comprehensive exhaust emissions testing equipment to satisfy all requirements of the new WLTC test procedure.

Technical specifications

- Max altitude simulation: 5000m

- Climatic range: -40 °C to +60 °C

- Max solar loading: 950 W/sqm

- Humidity: 10 - 80 % relative humidity

- Air circulation: 70,000 m³/hr

Chassis dyno specifications

- Configuration 4WD

- Speed, Km/h 250

- Force, N 6400

- Power, kW 230 per axle

- Max Power, kW 450 per axle (Overload 30 secs every 5 mins)

- Wheel base, m 2.1 m min, 4.4 m max

- Axle weight, kg 2500 per axle

- Single CVS tunnel

- Heated clean intake

- Heated sample bags gas/diesel

- Feed and tail analyser

- N2O analyser (QCL)

All current and future emissions test cycles including:

- WLTC

- Federal

- Japanese

- RDE defined

Vehicle Development Centre [PDF; 108 KB]

Fahrzeug - Entwicklungszentrum [PDF; 103 KB]

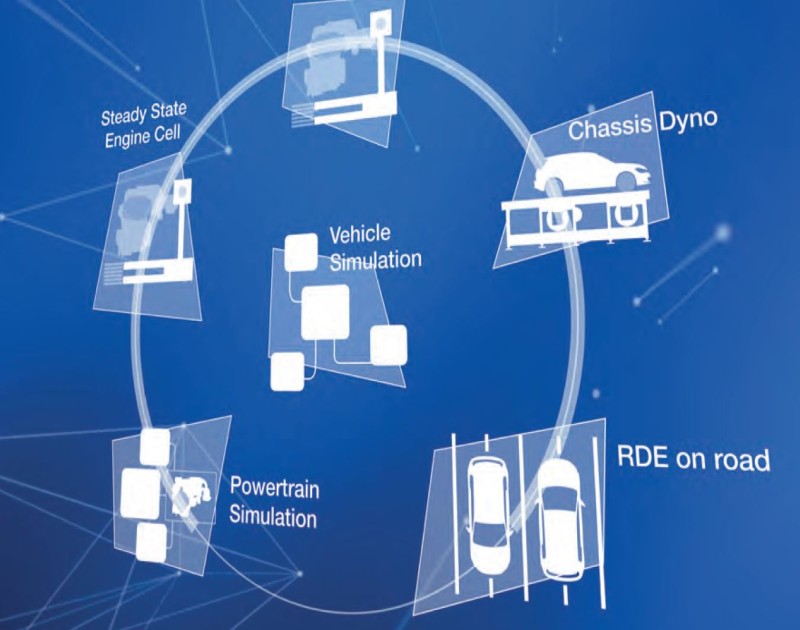

MAHLE Powertrain’s comprehensive RDE development process takes a holistic approach to the challenge of meeting the latest real world emissions targets. In order to achieve the optimum powertrain solution for any given vehicle application, a new test and development philosophy is now employed covering five key stages.

- Vehicle simulation

- Steady state powertrain testing

- Transient powertrain testing

- 4WD chassis dyno testing

- On road RDE testing

MAHLE Powertrain’s sophisticated vehicle simulation solution has been developed over many years, utilising several novel technologies and techniques to provide automotive engineers with RDE-ready powertrains in shorter timeframes than was previously thought possible. Our new approach has shown that the accurate simulation of RDE drive cycles upfront is fundamental to ensuring that emissions compliance can be achieved in a timely manner across all specified RDE conditions.

RDE Development Process [PDF; 1781 KB]

MAHLE Powertrain has expanded its extensive vehicle emissions testing capability at its Northampton, UK headquarters to include Portable Emissions Measurement System (PEMS) testing. This service further enhances our vehicle testing services and allows the precise measurement of tailpipe emissions whilst the vehicle is being driven on road.

PEMS testing forms part of the new RDE (real driving emissions) gaseous and particulate number (PN) legislation requirements for EU type approval. It also provides a more accurate measurement of fuel consumption / CO2 emissions during ‘real world’ driving conditions. MAHLE Powertrain was the first ESP to be certified by the VCA to perform legislative RDE emissions testing in 2017.

- Two Horiba OBS_ONE PEMS systems (including PN)

- Fully self-contained system mounted inside the vehicle

- Accurate measurements of CO, CO2, NO, NOx and PN

- Video capture included as legislative requirement

- Two VCA certified test routes based at Northampton site

- In-depth analysis of resulting data

Portable Emissions Measurement System (PEMS) [PDF; 1300 KB]