Transmissions (ZG)

MAHLE has recently acquired the German transmission specialist ZG-Zahnräder und Getriebe GmbH to further strengthen MAHLE Powertrain’s expertise in transmission design and gear optimisation. The newly formed MAHLE ZG Transmissions GmbH is a future-oriented and innovative service provider in the field of gear technology with a range of customers including major automotive OEMs and Tier 1 suppliers. Our core competence lies in the development and production of innovative gears, often in the area of electric or hybridised drive concepts. MAHLE ZG Transmissions GmbH supports their customers throughout the entire development process – from the initial concept to fully validated prototypes.

Transmission Design & Development [PDF; 938 KB]

MAHLE ZG Transmissions GmbH provides all the essential work steps of the entire gear development process. The whole project – from the idea, via the gear structure synthesis and detailed engineering, to the assembly and testing of prototypes – will be managed by the ZG company.

We pay special attention to a complete documentation. The entire history of development with all relevant outcomes will be recorded by means of a PDM system. It begins with the documentation of initial ideas and ends with the complete and individual recording of all data required for the full validation of assembled and tested prototypes.

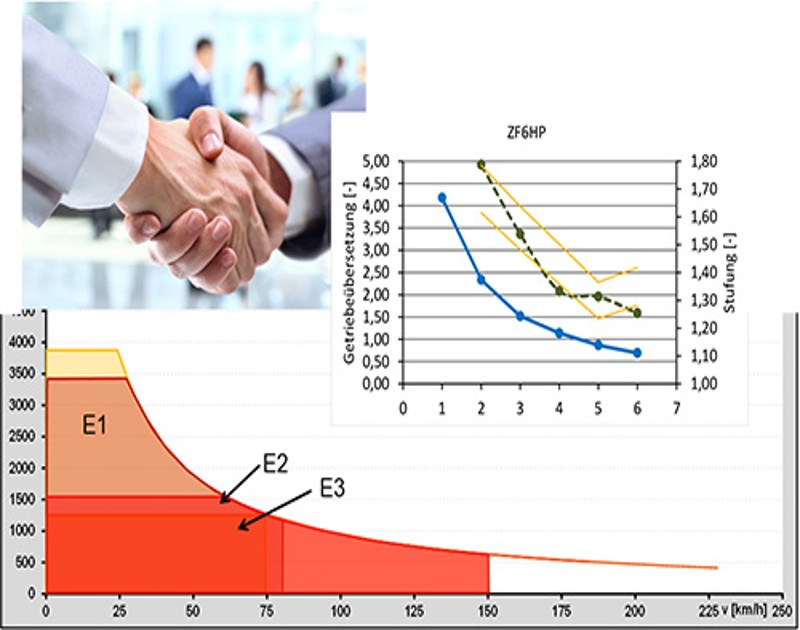

Development of the idea (gear) together with the customer, according to the customer’s ideas and specifications and the technical framework.

The expertise of MAHLE ZG Transmissions GmbH, based on many years’ experience, helps in the definition of appropriate criteria serving as a basis for the gear synthesis to follow. Thus, the gear structures to be identified can be determined in analysable numbers.

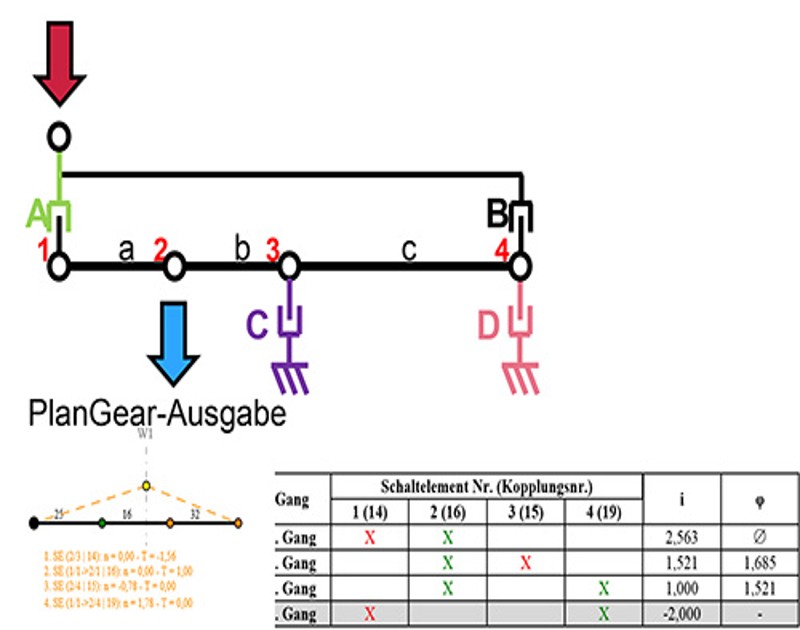

- The identification of possible gear structures is termed “gear synthesis”.

- MAHLE ZG Transmissions GmbH resorts to “PlanGear”, an in-house software for gear synthesis.

- “PlanGear” uses desktop or mainframe computers for its calculations – depending on the complexity of the respective problem.

- For this purpose, ZG developed an algorithm based on a beam-analogy model.

- Fully-automated gear synthesis is, therefore, possible for automatic, dual clutch and hybrid gears. On principle, the gears can consist of any number of shafts, spur gear stages and planetary gears.

- The visual display of the gear mechanics, switching matrix, capacity load matrix, etc., and the corresponding ranking will be the outcome of the synthesis

- Based on the gear mechanics, “PlanGear” will propose several gear structures (e.g. a Ravigneaux gear set).

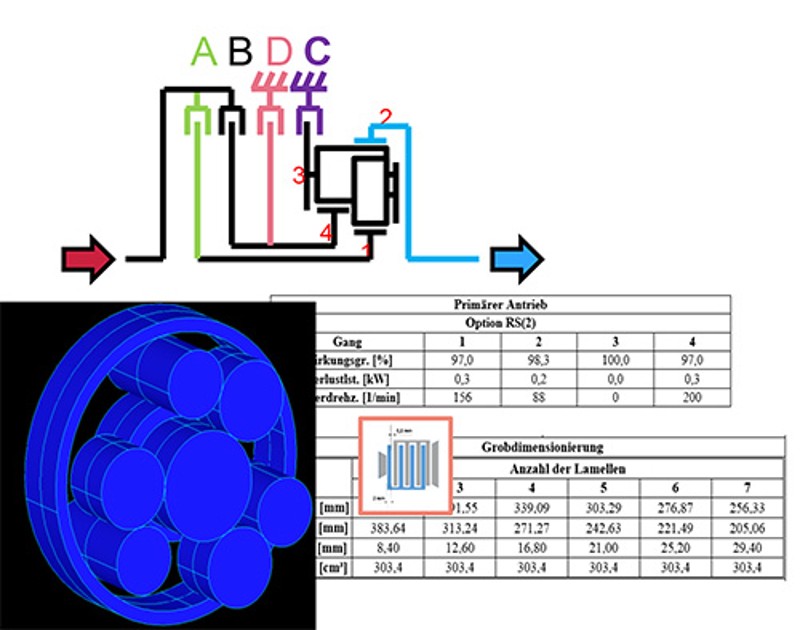

- The essential elements of the gear, such as gearings and switching elements, will be dimensioned automatically.

- The last step of the synthesis is the creation of the line sketch and the corresponding rough construction.

- ZG carries out the construction – from the first line to the completed set of drawings for all gear components

- ZG has sophisticated gear calculation software, such as “MASTA” from SMT.

- ZG’s expertise in the field of gearing design, particularly in the design of planetary and bevel gears, is the guarantee of efficient gearings with inconspicuous acoustics and a high level of load capacity.

- MAHLE ZG Transmissions GmbH has been realising housing constructions (pressure die and sand casting) for many years.

- Constructions will normally be accompanied by FEM calculations of the strength and deformation.

ZG provides all components of a gear. We rely on a network of suppliers ensuring the production of the components.

Prototypes are assembled in our own workshop.

One specific challenge in the pre-production of products is the systematic documentation of all production and assembly stages. Only then, the causes of possible failure can be determined categorically in field tests. The ZG company has a special software for documentation work.

- Initial function tests for assembled gears can be performed at our facilities near Ingolstadt.

- Lubrication tests performed at special test facilities guarantee operational safety under all subsequent conditions.

- The expertise of MAHLE ZG Transmissions GmbH, based on many years’ experience, makes sure that the test results will be evaluated in a reliable way.

Transmission design & development services

Gear Synthesis

The term “gear synthesis” in the field of gear-wheel drives, usually refers to the systematic identification of the structures. Here, a specific gear structure is characterised by the type and number of gear-wheel stages as well as the gear-wheel connections via fixed shafts.

It is always possible to meet specific gear requirements by means of numerous different gear structures representing the solution space.

Regarding vehicle gears, the solution space can amount to a size, even for a small number of gears (e.g. two-speed electric drive systems), that makes the time- and cost-efficient analysis of the solution space and, thus, finding the most favourable solution for the requirement impossible.

Therefore, MAHLE ZG Transmissions GmbH have been applying the “PlanGear” gear synthesis programme since 2010. The “PlanGear” program is a 100 % in-house-development by ZG and is being continuously enhanced. The program is based entirely on an algorithm which we developed. This algorithm enables a very efficient structure search for most different types of gear, such as:

- Non-power shift gears (e.g. manual gear-boxes)

- Power shift gears with one power-shifting element only

- Automatic power shift gears (e.g. torque-converter gear-box)

- Dual clutch gear-box

- Combinations, such as those with dual clutch and automatic gear-boxes

- All gear structures can consist of designs of planetary gears, such as Ravigneaux or Wolfrom planetary gear sets. They can also contain spur gear stages arranged on any number of wave-trains.

Since those hybrid gear-boxes, mostly driven by combustion engines or electric machines, are of great interest in the vehicles sector, “Plan Gear” has been equipped with manifold functions enabling the finding and assessing of such gear structures. One example of this is the so-called DHT (“Dedicated Hybrid Transmission”) gear-boxes that can be created for a wide range of requirements without much effort.

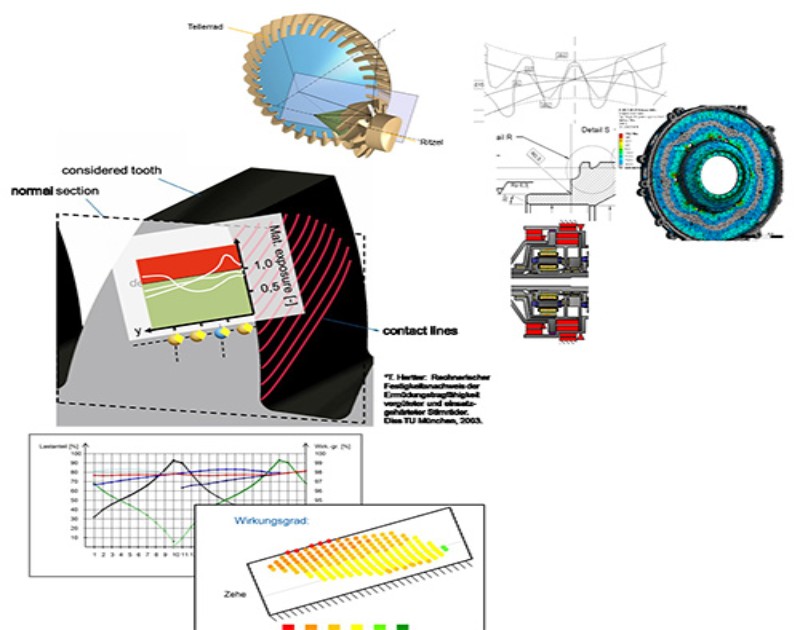

Gearing Calculations

The following programs enable the accurate calculation of the gear properties and the creation of gearing data relevant to construction:

- MASTA (SMT)

- Ansys

- Kisssoft

- Rikor (FVA)

It is possible to observe the behaviour of the entire gear system by means of the MASTA software. The calculation of one gear component often turns out to be sufficiently accurate only if the impact of the gear environment is also taken into consideration.

The gear environment, for example, must be considered for the optimisation of the rotational error of a spur gear stage by means of flank modifications. The deformation impact of shafts, bearings, thin-wall components and the gear housing are part of the gear environment. Since all elements cannot be determined analytically when there are complex geometries, the Ansys software will create reduced stiffness matrixes to be incorporated into the calculation with MASTA.

Spur & Helical Gears

MAHLE ZG Transmissions GmbH provides support from the initial idea to the production drawing by means of their vast knowledge in the field of gear wheel development.

- Design of any spur and helical gears, independent of type and material

- Performance of environmental analysis

- FEM analysis

- Creation of detailed production drawings

- Support for the selection of the production tools

- Supply of prototype parts

The following software packages are available in addition to our in-house software:

- KISSsoft

- MASTA (SMT)

- ANSYS

- STPlus (FVA)

- Rikor (FVA)

Bevel & Hypoid Gears

MAHLE ZG Transmissions GmbH, with their vast expertise in the field of bevel gears, designs any type of straight or spiral bevel and hypoid gears.

- Calculation of the ease-off and tool/machine set-up data for any machine (including 5-axis CNC machines)

- Performance of local analysis from gearing efficiency grade to the calculation of the flank breakage load capacity

- Calculation of the deviations from the positioning of the axis under load

- Support for the production and/or delivery of prototype parts

Regarding bevel gear calculations, MAHLE ZG Transmissions GmbH works closely with ZG Hypoid Gmbh (www.zg-hypoid.de). The software “ZG Suite” developed in-house is available for recalculation and variant calculation of macro geometry. “LokAna”, our programme developed in-house, enables extensive analyses based on local approaches. The FVA software packages BeCal and KNPlus are available for additional investigations too.

Special Gears

MAHLE ZG Transmissions GmbH is experienced in the design of any type of gears, for example, familiar types of gears, such as worm, crown, beveloid or novel gears.

- Calculation of the ease-off and tool/machine set-up data for any machine

- Performance of load capacity and FEM calculations

- Support for the production and/or delivery of prototype parts

Regarding special gears, MAHLE ZG Transmissions GmbH works closely with Involute Simulation Softwares Inc. (www.hygears.com).

In addition to this, the following software packages are available:

- KISSsoft

- ANSYS

Gear Construction

MAHLE ZG Transmissions GmbH is equipped with numerous established CAD programmes and the respective development environments.

In co-operation with our customers, we take care of the construction from the basic component and assembly frame, through the dimensioning and detailing of the components and the engineering drawing, to the list of parts.

We resort to sophisticated calculation programmes to achieve the optimal design of components in line with the construction.

Housing Construction

MAHLE ZG Transmissions GmbH provides expertise in the field of housing construction in all current procedures – sand, die and pressure die casting – all according to our customers’ demands.

We see to the development from the initial design sketch to the finished housing drawing. We pay specific attention to the issue of producibility during the whole development process.

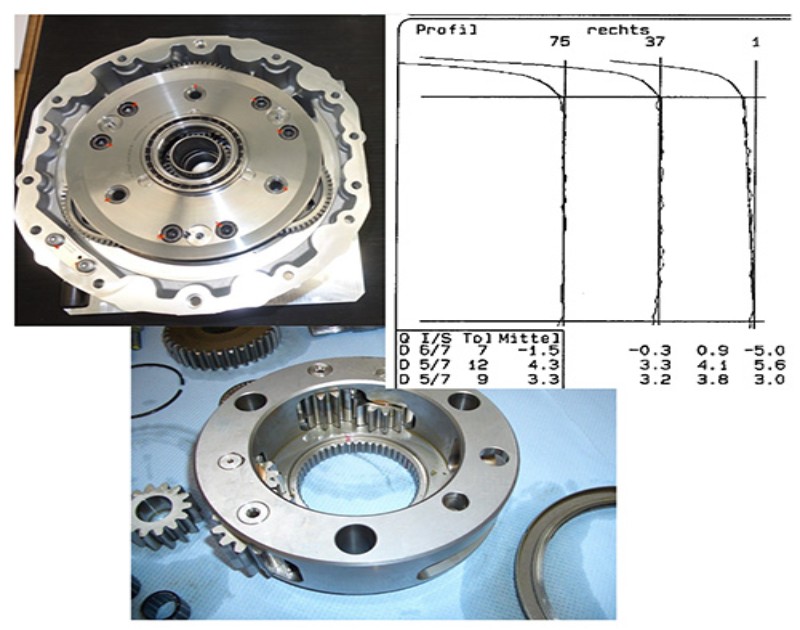

Prototype Manufacture

Prototypes represent a significant milestone in the development of new products.

MAHLE ZG Transmissions GmbH achieves this milestone together with their selected partners – no matter whether “only” a gear wheel or an entire gearing (e.g. an automatic gear for cars) is required.

- Creation of production-oriented drawings

- Review of drawings with manufacturers

- Component modifications management (introduction of modifications related to production)

- Attending the production (on-site appointments with manufacturers)

- Check/Dimensioning of components

- Assembly of gear prototypes (at first, virtual assembly)

- Complete documentation of prototypes in the ZG database, this means, for example, the keeping of a log file during gear assembly or the monitoring of all press-in forces through the corresponding sensor system

Component Testing

MAHLE ZG Transmissions GmbH has two test facilities for the testing of components.

Along with the development process, components such as innovative seals and complete gear systems will be tested under load-free conditions.

Analysing the lubrication inside a gear is enabled by means of a swivel test stand enabling internal analysis.

Failure Analysis

Based on many years’ experience, we assess different types of failures connected with gears, such as:

- Gearing failures

- Bearing failures

- Shaft failures

- Housing failures

Detailed inspection of the gear system is essential for relevant failure analysis. For this purpose, we rely on sophisticated software such as:

- MASTA

- HyGEARS

- Ansys

- Rikor

and our in-house software:

- PlanGear

- ZGSuite

- LokAna

Consulting

MAHLE ZG Transmissions GmbH provides consulting and training in the fields of:

- Basics on gearings

- Gear synthesis (identification of the structures)

- Planetary gears

- Bevel and hypoid gears , independent of manufacturer and production systems

- Special gearings

- Manufacturing/Production