MAHLE Jet Ignition®

A new pre-chamber ignition system

The MAHLE Jet Ignition® system is a new combustion technology which replaces the standard spark plug in SI engines with a jet ignition pre-chamber assembly, without requiring a separate ignitior within the main combustion chamber.

MAHLE Powertrain has been developing the pre-chamber based system over the last 10 years, in both ‘Passive’ and ‘Active’ configurations and has applied the technology to a wide variety of multi-cylinder applications ranging from passenger cars to motorsport, heavy-duty and stationary engines.

Passive and active systems

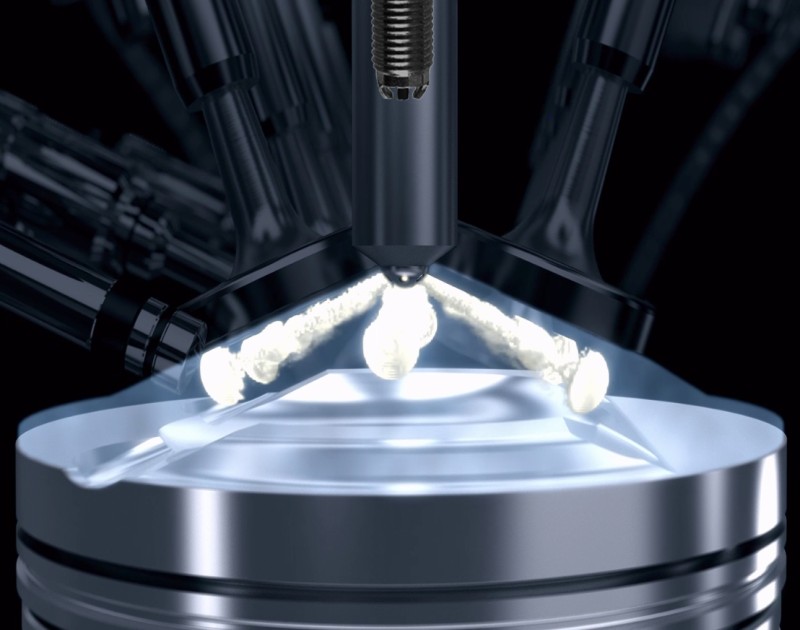

In both ‘Passive’ and ‘Active’ configurations the MAHLE Jet Ignition® system’s combustion is much faster than with standard spark ignition, enabling the engine to operate closer to optimum spark timing as the knock limit is extended significantly. This provides the ability to either increase the compression ratio, to improve efficiency, or to extend the performance that can be achieved under stoichiometric operating conditions.

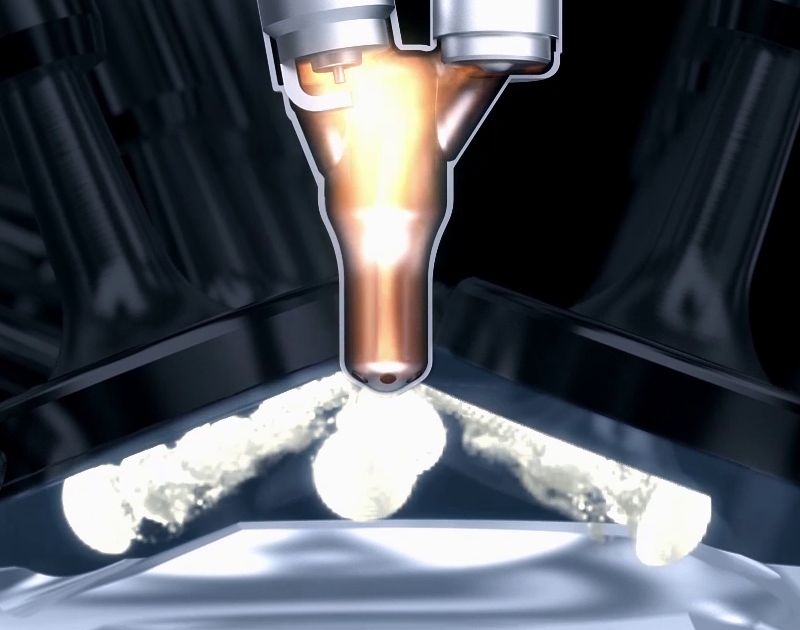

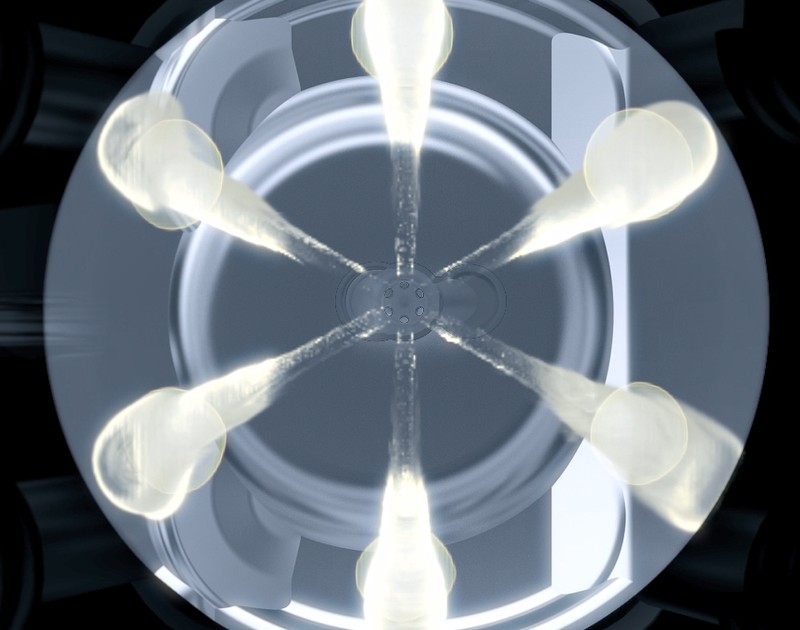

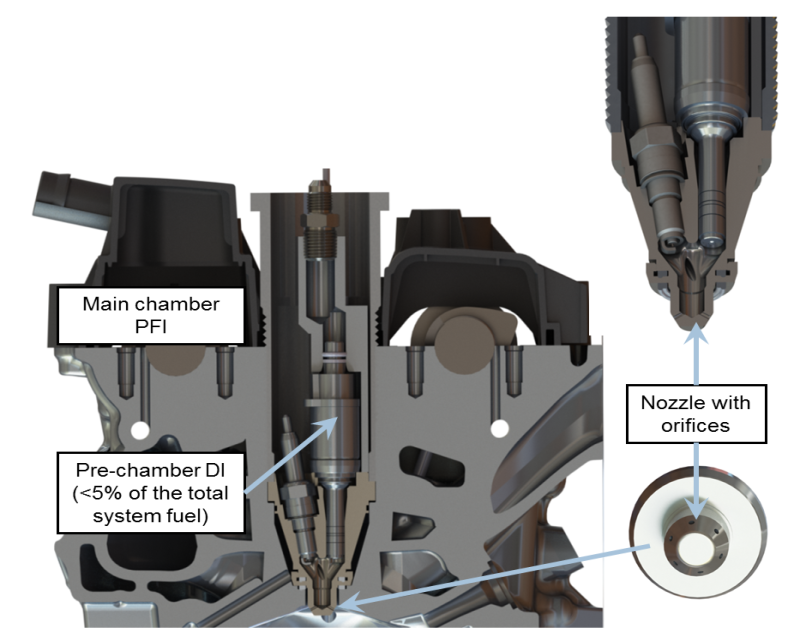

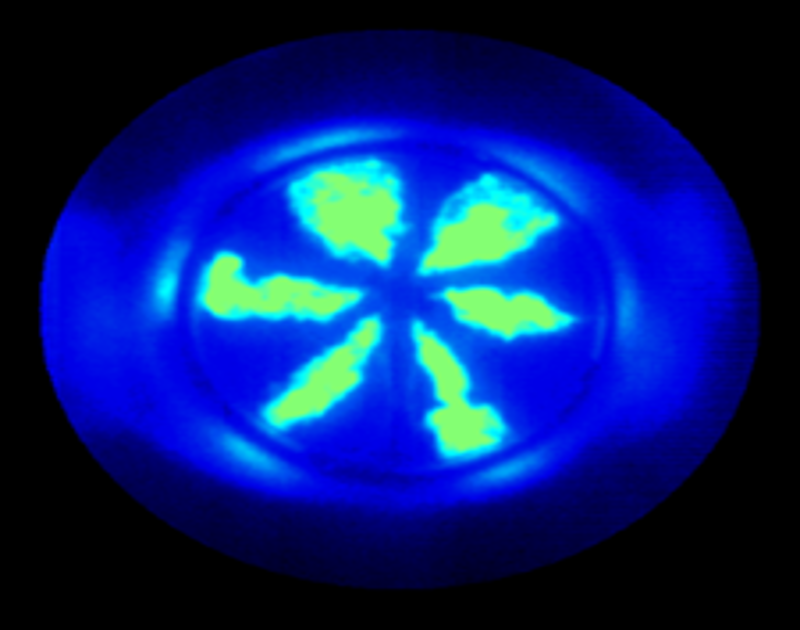

The MAHLE Jet Ignition® system features a small ignition chamber, housing a conventional spark plug, which is connected to the main chamber by a number of small orifices that create fast moving jets of partially combusted products which ignite the main charge. These hot gas jets penetrate deep into the main combustion chamber to create a distributed ignition effect. With 4-8 ignition jets, depending on the application, the main charge is ignited at multiple sites, resulting in a rapid and stable combustion. The characteristics of the system offer further benefits through both the ability to ignite dilute mixtures and the reduced requirement for high levels of port induced charge motion.

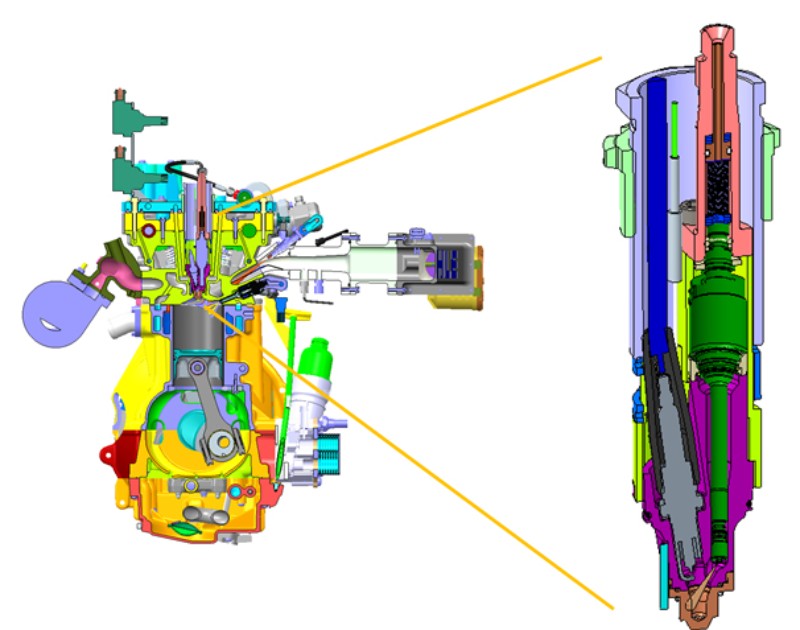

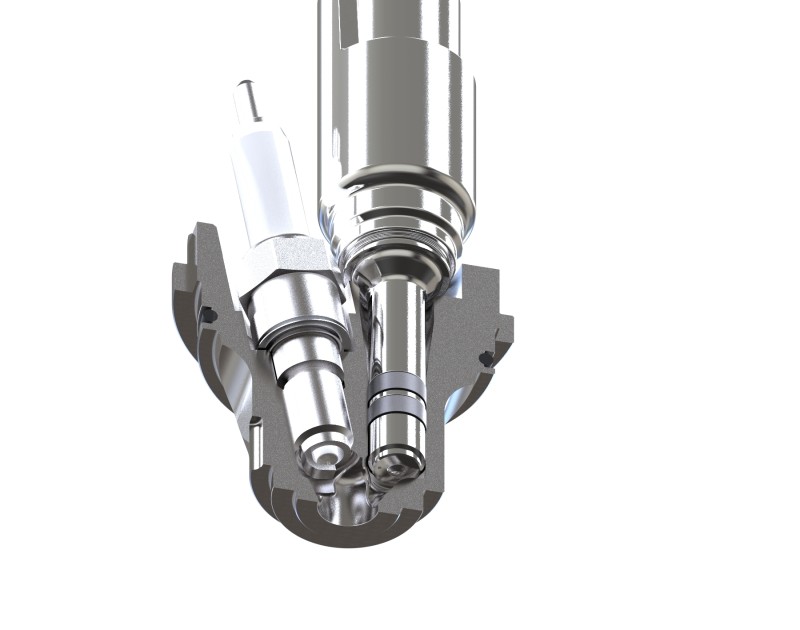

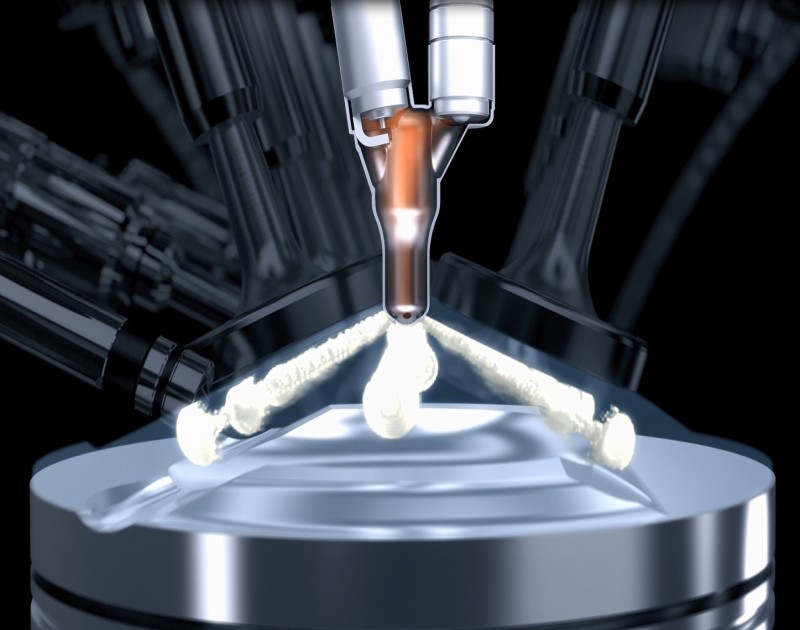

In both configurations the main chamber is fuelled through a conventional port or direct-injection injector. In the ‘Passive’ configuration, this is the sole source of fuelling making this arrangement suitable for use in λ=1 applications, with dilution being provided through the addition of exhaust gas recirculation (EGR). This system is compatible with conventional gasoline aftertreatment systems. In the ‘Active’ configuration a 2nd low-flow direct injector is incorporated into the pre-chamber assembly. This allows fuelling to be accurately, and independently, controlled in both the pre-chamber and the main chamber, enabling homogeneous ultra-lean combustion in modern gasoline engines, where mixtures leaner than λ=2 can be ignited while retaining stability.

In addition to the work on customer applications for both systems, research continues internally, using versions of our own 1.5l, 3-cylinder technology demonstrator engine. On this engine, the Passive MAHLE Jet Ignition®, that can typically be packaged within the same casting as a conventional M12 sparkplug installation, has demonstrated the capability to achieve whole map operation for both prime-mover and dedicated hybrid engine applications. Using a combination of Passive MAHLE Jet Ignition®, very high geometric compression ratio, port fuel injection, Miller-cycle operation and low-pressure EGR over 41% brake thermal efficiency has been demonstrated.

In the Active MAHLE Jet Ignition® configuration, significant fuel savings are achieved by the higher, almost diesel-like efficiency. Engine tests have shown specific consumption below 200g / kWh and related reductions in CO2 emissions. This is equivalent to a current peak BTE of 43%, with a road-map of work planned to achieve >45% BTE. In addition to providing efficiency and fuel consumption advantages, Active MAHLE Jet Ignition® also achieves reductions in engine-out NOx emissions by more than 99% in the ultra-lean area. Hydrocarbon (HC) emissions are maintained at levels equivalent to standard spark ignition operation. Active MAHLE Jet Ignition® (with PFI main chamber fuelling) generates slightly elevated particulates compared to a PFI engine but these are significantly reduced versus a DI engine.

In both ‘Passive’ and ‘Active’ guises, the pre-chamber has been developed such that it is capable of enabling comparable idle and catalyst heating spark retard capability and feed gas emissions to a central spark plug, under stoichiometric conditions, without the requirement for a 2nd ignitor within the main chamber.

MJI increases burn rates and widens the stable dilution range, therefore it can accommodate a wide range of fuel types and is an ideal enabling technology for future low carbon fuels with specific operating requirements. Hydrogen, for example, requires high levels of dilution to minimize abnormal combustion likelihood and prevent mechanical damage to the engine. MJI H2 engines have demonstrated the ability to achieve high power levels while achieving comparable well-to-wheel CO2 emissions to equivalent fuel cells.

MAHLE Jet Ignition® is an exciting new combustion system that provides great potential for further CO2 emissions reduction in latest generation gasoline engines.

MAHLE Jet Ignition® Passive [PDF; 1201 KB]

MAHLE Jet Ignition® Active [PDF; 1269 KB]

MAHLE Jet Ignition® - Active system